Supervision system for ceramics plant.

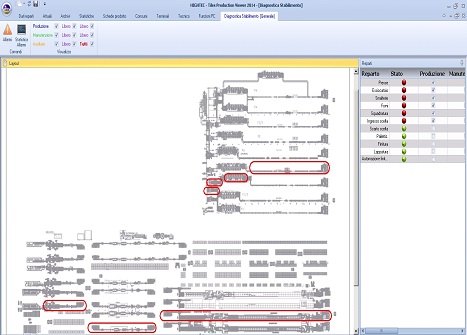

Complete production tracking from pressing to palletisation.

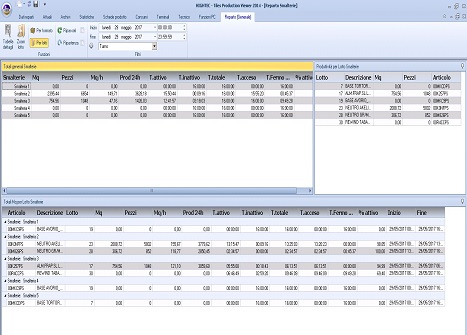

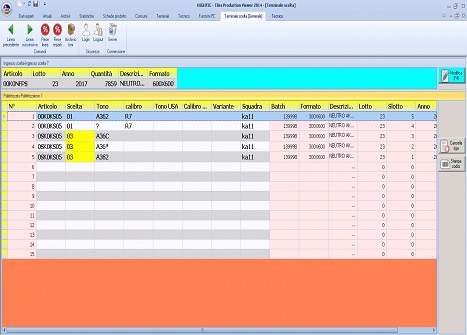

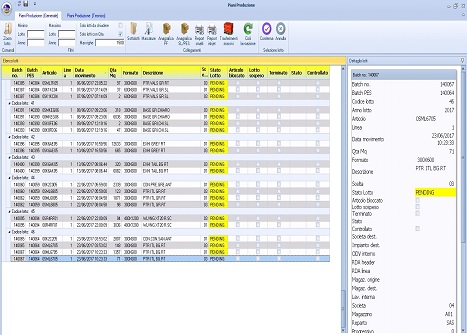

Production plan reception from management system for processing the various batches

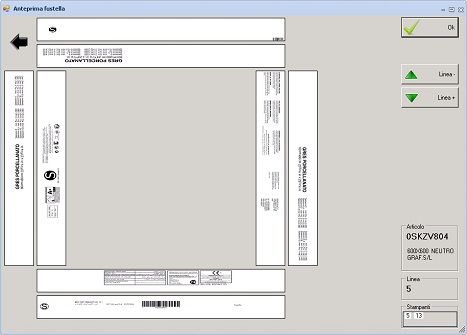

Printer message management for marking boxes exiting wrapp

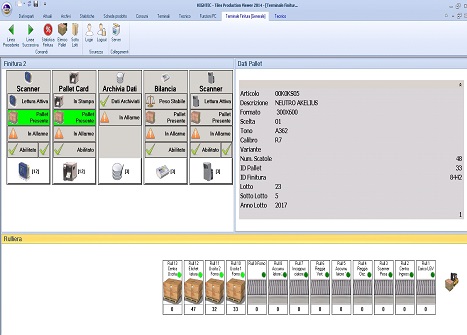

Box code identification on pallet entering the stretch-hooding line, for pallet card printing

Transmission of product pallet data to management system.

Production counter management divided by production batch and by department.

Calculations divided by department and by production batch.

Collection of alarms from the various departments and display on alphanumeric luminous notice boards

Alarm and counter statistics management for scheduled maintenance

Automatic transmission of alarm notifications and/or other important events via SMS and/or E-mail to department managers, reference staff or available technicians.